Line tails are important for both efficiency of the mooring operation and the safety of the moor handlers. If the purchasing managers choose the lowest cost and less-resilient mooring tail, it will create dangerousness and re-purchase in the short run. According to Harald Dieter, the head of the Heisenberg Ship Chandler division, the mooring tails are paying back their cost, if they are chosen properly according to their resistance, material made of, and so on.

According to a study made by UK P&I CLUB, Many accidents have occurred during the handling of ropes/wires, where ropes/wires have parted (53%) or where ropes/wires have jumped/slipped off drum ends/bitts (42%) with 5% caused by actual equipment failure (see pie chart below center).

In this subject, there are many different practices accepted across the industry since the inspections of respected authorities mainly focus on the physical condition of the ropes/tails in terms of wear and tear. If the ropes/tails look in good condition, or new, then the inspectors give the green check for them. However, there is more undermatch of this subject.

Oil Companies International Marine Forum (OCIMF), in report dd 2022, has stated that it is highly recommended to use at least 25% more strong tails than the actual rope itself. The reason behind this approach is to make sure that the tail is able to carry the mass that the rope transfers to it.

Most of the time, as Heisenberg Shipping’s Ships Supply division, we see that the purchasing managers are ordering ropes and lines at the same time and preferring fewer strength tails than the rope itself. The logic behind this behavior is to make sure that in case of an overpressure situation the tail breaks first.

Replacing the tail is much easier than replacing the rope. However, our sourcing operations team always advises the opposite and acts in line with the practice defined by OCIMF.

In an ideal scenario, with a brand-new tail and rope, they must go along as long as their manufacturers advise to use unless an unexpected situation occurs and then be replaced together without being in fear of potential sudden breaking of the tail during the mooring operations. In such cases, we highly advise Masters also to take this into consideration and recommend supplying tails in proper strength to make sure that a long run and safe usage of the rope and tail assembly.

Economical Aspects of Choosing the Right Tail

Tail Shall be More Strong than the Rope

Our experienced Ships Supply team has stated that when the owners/operators/charterers order such low quality/strength tails, it is statistically proven that the tail will need to be replaced much earlier than the rope and this actually creates double cost in the long run. The price difference between low-strength and high-strength tails is not linear so with a 25% – 30% premium, a high-strength tail can be purchased and in the long run, it will be economically beneficial to the party ordering.

Of course, we are not only supposed to determine the purchasing decision from the economical perspective but also we are expected to assess the purchasing decision by thinking about the safety of the mooring operations. UK P&I club has a great report that shows how improper ropes, and tails may create huge damage to seafarers and line handlines at the shore.

Safety Alert Under Potential Line Breaking Situation

Seafarers Must Identify the Safety Zones on Deck

Our experienced Ships Supply team has stated that when the owners/operators/charterers order such low quality/strength tails, it is statistically proven that the tail will need to be replaced much earlier than the rope and this actually creates double cost in the long run. The price difference between low-strength and high-strength tails is not linear so with a 25% – 30% premium, a high-strength tail can be purchased and in the long run, it will be economically beneficial to the party ordering.

Of course, we are not only supposed to determine the purchasing decision from the economical perspective but also we are expected to assess the purchasing decision by thinking about the safety of the mooring operations. UK P&I club has a great report that shows how improper ropes, and tails may create huge damage to seafarers and line handlines at the shore.

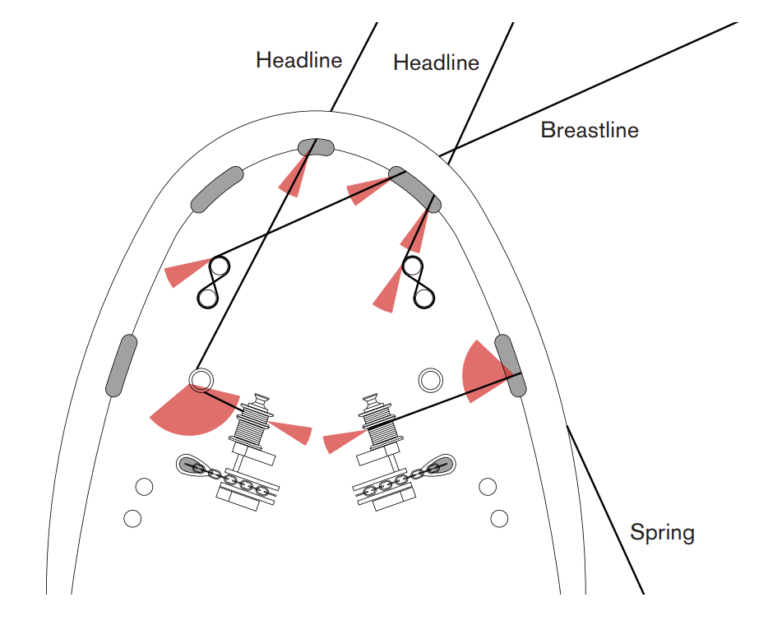

It is well known that the majority of serious incidents in mooring areas involve parting lines. It is very clear that every rope/tail has the potential to break due to various reasons under such high-pressure situations during mooring or unmooring operations at ports. Heisenberg Shipping advises not only to make sure to choose the proper tails and ropes for the purchasing people but also to suggest that the snap-back zones on the deck of the vessels under our agency are properly determined.

Painting these areas as seen in the above example helps the seafarers and officers to arrange the position of the mooring gang members properly to make sure that the safety of the people working on board is protected under an extraordinary situation occurs.

If you are looking for supplying ropes/tails on board of your vessel at a Turkish Port, please contact with our Ships Supply Team!

Discover Our Other Posts

On Deck Shipment