Deadweight Tonnage (DWT, D.W.T., d.w.t., or dwt) is commonly used to describe the total weight (in metric tons) a ship can safely carry. DWT includes the weight of the cargo, crew, fuel, provisions, water, ship’s constants, and all other materials on board.

In this article, we will dive deep into understanding Deadweight Tonnage (DWT) and its importance in today’s maritime industry. We will cover topics such as how DWT is measured, comparing DWT with other tonnage measurements, deadweight utilization, and why vessel tonnage measurement is crucial in shipping.

Whether you’re experienced or new, keep reading to become an expert on Deadweight Tonnage in the industry.

Understanding Deadweight Tonnage (DWT)

Indicator of a Ship’s Overall Carrying Capacity

Deadweight tonnage is a crucial indicator of a ship’s overall carrying capacity in tonnes. It plays a significant role in determining a ship’s profitability and determining some of the fees and port dues.

DWT is calculated by subtracting the ship’s light displacement (known as lightweight) from its loaded displacement. Loaded displacement includes the ship’s own weight, cargo, fuel, and supplies onboard. On the other hand, light displacement is the weight of a ship with all its permanent additions, excluding the cargo, crew, fuel, provisions, water, and all other inconstant materials on board.

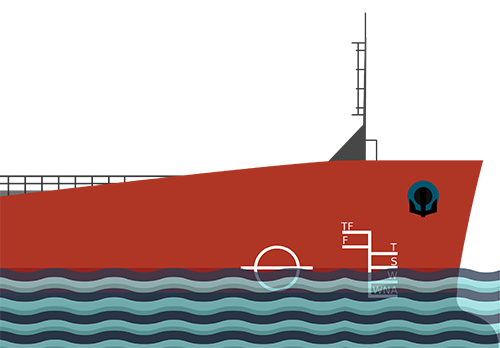

It should be noted that there are different types of deadweight tonnage, including lightship deadweight (LSDW) and summer deadweight (SDWT). LSDW refers to the vessel’s weight when it is empty, while SDWT refers to the maximum weight a ship can carry in summer months when water density is lower due to warmer temperatures.

Summer Deadweight(SDWT) is a critical parameter in maritime terms, representing the maximum weight a ship can carry during the summer season. A ship can be loaded down to her Summer Loadline to reach its Summer Deadweight. The information about the load line zones can be found in World Load Line and International Time Zones.

By considering all these factors, shippers/charterers can make informed decisions about their cargo and optimize their operations for success.

“The deadweight of a ship measures the total weight of cargo that the vessel can carry when loaded down to its marks, including the weight of fuel, stores, water ballast, fresh water, crew, passengers and baggage.”

Stopford, M. (2009). Maritime Economics.Taylor & Francis Group.

How is DWT Measured?

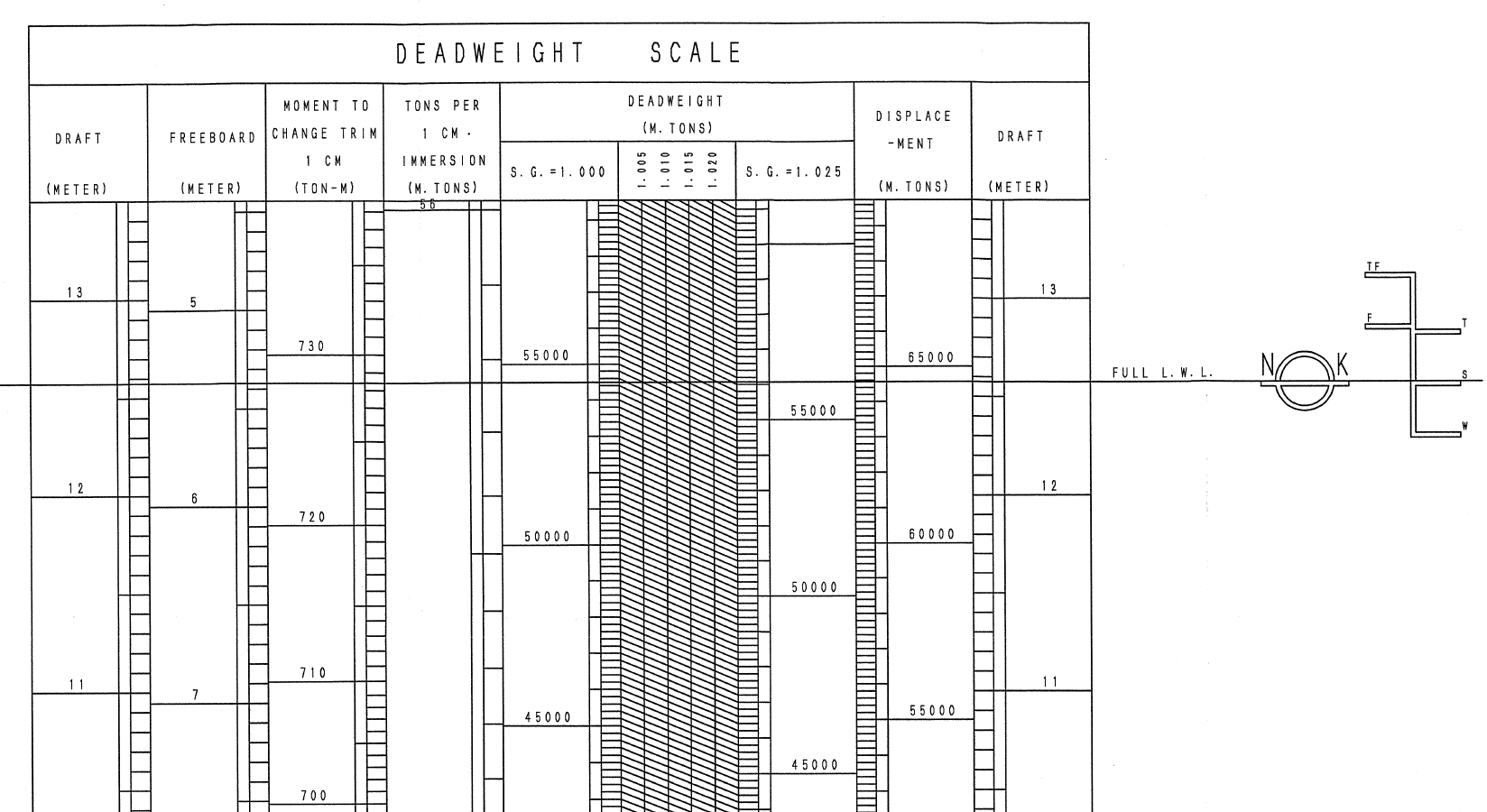

Design Parameters, Draft Readings and Deadweight Scale

The first step to determining the DWT is to calculate the fully loaded weight of a vessel with its design parameters, such as light displacement. A ship’s Deadweight Tonnage (DWT) measurement represents a blend of design foresight and on-site assessment, such as a draft survey.

At the heart of DWT lies the total weight a ship can safely carry, encompassing cargo, crew, fuel, provisions, and more. Initial calculations arise during a vessel’s design phase, where naval architects anticipate its weight-carrying potential based on design and materials. This method ensures the ship’s loading remains within safe limits, harmonizing design predictions with real-world scenarios.

International conventions regulate DWT measurement using the ship’s displacement and registration documents. Accurate measurement ensures compliance with safety regulations. This basis for measuring DWT contributes to the excellence and reliability of shipping operations.

Each vessel has a chart called the “Deadweight Scale.” This is a predefined chart made upon the final tests of the vessel at the shipbuilding yard. It includes the design displacement tonnages, deadweight capacities, and tons per cm at each draft level, which are written in this chart. This gives a reference point to measure the vessel’s dwt at a given draft.

In essence, the measurement of DWT is a combination of design data, physical measurements (like draft readings), and standard reference materials like hydrostatic tables. The goal is to ensure that a ship is only loaded within its safe carrying capacity.

Comparing DWT with Other Tonnage Measurements

DWCC, Gross Tonnage, Net Tonnage and Light Displacement Tonnage

Comparing DWT with other tonnage measurements is crucial for effective ship management. While DWT measures a ship’s weight, other measurements focus on different aspects. By understanding these differences, ship operators can gain a comprehensive view of a ship’s capabilities.

Each tonnage measurement serves a specific purpose in the shipping industry, providing a basis for calculating available space, volume of water displaced, and cargo-carrying capacity. This knowledge allows for excellence in vessel utilization and optimizing profitability.

DWCC vs. DWT

Deadweight Cargo Carrying Capacity vs. Deadweight Tonnage

The maritime industry’s commercial players consider DWCC and DWT critical for shippers and charterers.

DWCC measures the weight of cargo a vessel can carry, while DWT measures the total weight a ship can carry, including cargo, fuel, and supplies.

To ensure efficient and profitable cargo transportation, it is essential to maximize both DWCC and DWT. The distinction between these terms is vital for operational safety and commercial viability. While ship operators and owners prioritize DWT to ensure the vessel’s safety and compliance with maritime regulations, charterers, mainly concerned with revenue, emphasize DWCC.

After all, the DWCC determines the cargo weight – and thus freight income – for a specific voyage. Grasping the nuances of DWT and DWCC is essential for anyone seeking to successfully navigate the complex waters of the shipping industry as a charterer, shipowner, or shipbroker.

Gross Tonnage vs. DWT

Gross Tonnage, All the Closed Areas on Board

Gross tonnage and DWT are important indicators of a ship’s capabilities and characteristics. While gross tonnage measures the total internal volume of a ship, DWT focuses on the weight a ship can safely carry. Gross tonnage includes spaces necessary for operation, like engine rooms and crew quarters, while DWT considers cargo, fuel, and supplies. Comparing these measurements provides insights into a ship’s size and carrying capacity.

Net Tonnage vs. DWT

NetTonnage, All the Closed Areas on Board for Cargo

Net tonnage and deadweight tonnage (DWT) are important considerations in shipping operations. Net tonnage measures the available cargo space on a ship, excluding non-cargo areas. On the other hand, DWT focuses on the weight the ship can carry, including cargo, fuel, and supplies.

Understanding the relationship between net tonnage and DWT is crucial for efficient cargo transportation. By maximizing net tonnage and DWT, shipowners can ensure they have the necessary space and carrying capacity to meet the charterers’ needs.

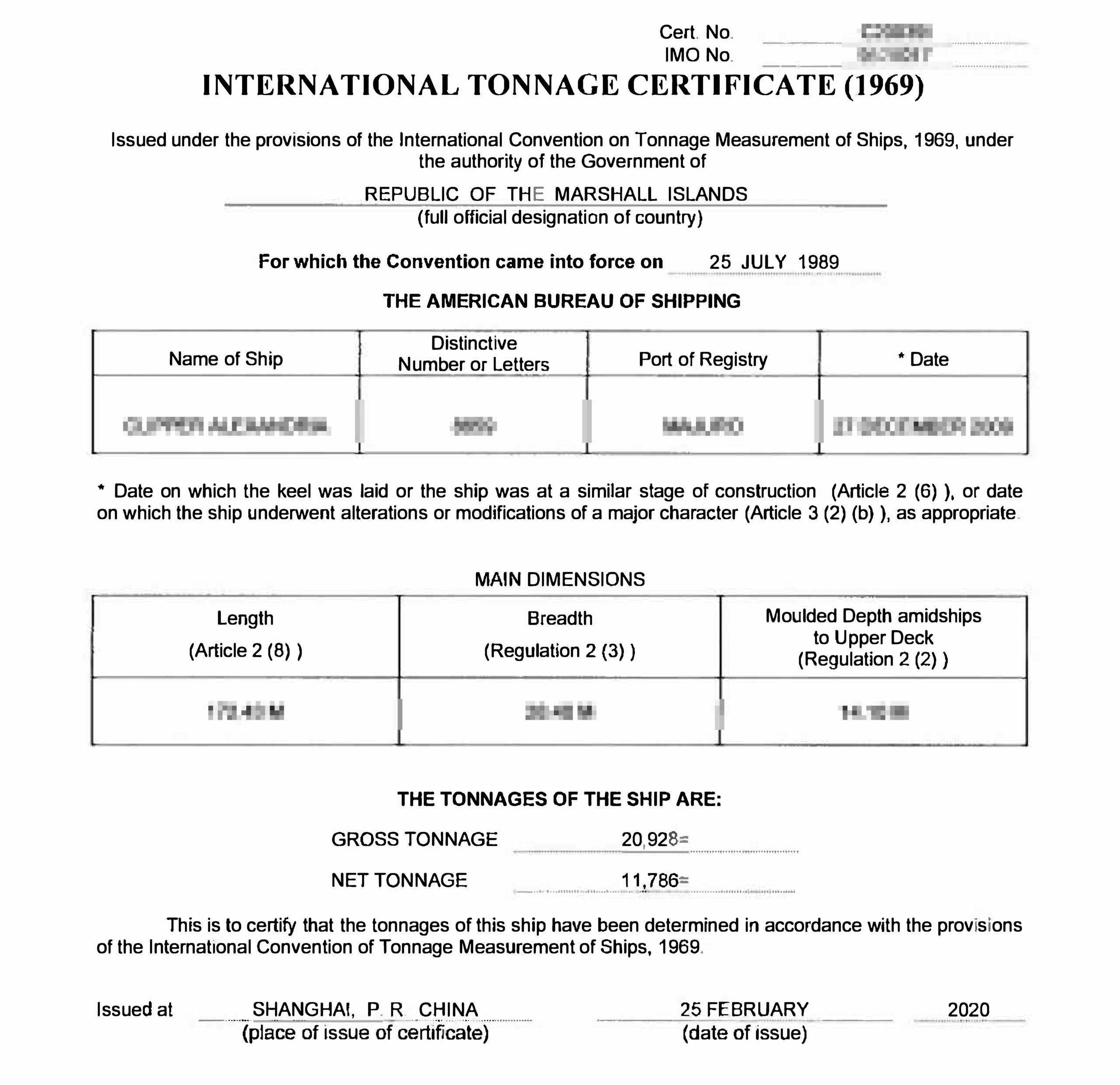

Net Tonnage and Gross Tonnages are certified measurements of a ship under The International Tonnage Certificate (1969). The International Tonnage Certificate (1969) is a crucial document that validates a vessel’s tonnage as measured in compliance with the International Convention on Tonnage Measurement of Ships, 1969. This certificate specifies the Gross Tonnage (GT) and Net Tonnage (NT) of a ship, calculated based on a standardized formula that takes into account the vessel’s internal volume and cargo space. Issued by a flag state or an authorized body, the certificate is essential for various administrative and operational aspects of maritime activities.

Having a valid International Tonnage Certificate is a prerequisite for international voyages and is recognized universally, thus facilitating smoother maritime operations and regulatory compliance.

Light Displacement Tonnage (L.D.T.)

LDT: Total Weight of the Water the Ship Displaces

Light Displacement Tonnage (L.D.T.) or ship displacement or displacement tonnage refers to the weight of a ship without cargo, fuel, or supplies. The measurement is done indirectly, utilizing Archimedes’ principle. It involves calculating the amount of water the ship displaces and converting this volume into weight.

L.D.T. serves as a baseline measurement for a ship’s weight and has various applications, such as vessel registration and determining port fees. Accurate measurement of L.D.T. is crucial for compliance with regulations and safety standards. Managing and operating ships effectively relies on understanding and monitoring the ship’s light displacement tonnage.

Displacement Tonnage vs. DWT

LDT vs. DWT

Displacement tonnage and DWT are two important measurements in the maritime industry. Displacement tonnage refers to the weight of water displaced by a ship, while DWT measures the weight the ship can carry. While the ship’s displacement tonnage is influenced by the ship’s design and structure, the ship’s deadweight tonnage focuses on the weight the ship can safely carry, including cargo, fuel, and supplies. Understanding the relationship between these two measurements provides valuable insights into a ship’s capabilities and has implications for chartering, ship demolition, and ship management.

Deadweight Utilization

More Bunkers or More Cargo?

Deadweight utilization in shipping refers to the cargo capacity lost due to bunkers, stores, and other weights on board preventing a full cargo load. This can impact fleet productivity and overall efficiency. It quantifies the proportion of a ship’s deadweight tonnage (DWT) utilized for transporting cargo.

A ship with a high deadweight utilization effectively leverages its carrying capacity (DWCC). This enables to ensure that most of its weight-bearing potential is dedicated to revenue-generating cargo.

On the other hand, a low deadweight utilization indicates that the ship is transporting a significant amount of weight except cargo, such as ballast or excess fuel, and freshwater, which don’t contribute directly to the revenue.

Achieving optimal deadweight utilization is often a balancing act. While maximizing cargo load is beneficial from a revenue perspective, operators must also consider other variables like fuel for the subject voyage, provisions for the crew, and ballast for stability.

Efficient maritime operations aim for a sweet spot: maximizing deadweight utilization while ensuring the vessel remains safe, stable, and compliant with international regulations.

Importance of Deadweight Tonnage in the Maritime Industry

Industry’s Standard for Classification of Ships: DWT

Deadweight Tonnage (DWT) stands out as an essential commercial element of shipping operations where precision meets practicality. It forms the backbone of ship specifications and is vital for draft considerations and the Plimsoll mark. It is the primary metric for understanding the ship’s type and capacity. Its accurate assessment ensures that a ship remains seaworthy, stable, and well within safety regulations during voyages.

DWT is not just a standalone factor. It plays an essential part in the commercial management of vessels. Even some ports restrict their berths up to certain Deadweight Tonnages. Therefore, DWT, along with other measures like Gross Tonnage (G.T.) and Net Tonnage (N.T.), limits what shipowners or charterers can do and determines the costs.

Additionally, DWT helps categorize ships when registered, ensuring they meet set standards and rules. In this way, commercial players such as charterers or shipbrokers report the fixtures to build the global market understanding of the shipping at a given time. For example, There are indexes called The Baltic Dry Index. These indexes are published daily and classify ships according to their DWT.

In conclusion, understanding deadweight tonnage is crucial in the maritime industry. It plays a significant role in ship design, construction, and cargo carrying capacity calculations. Deadweight tonnage measures the total weight a vessel can carry, including cargo, fuel, water, and supplies. It is important to note that deadweight tonnage does not reflect the actual cargo capacity, as other factors can limit the cargo a ship can carry.

Discover Our Other Posts

Dry Docking